Facility management software provides tools to record, schedule, assign, communicate and monitor all facility-related activities for quick and easy report generation for management decision making. It enables you to easily track the location, usage, maintenance history and total cost of ownership of your facilities and its’ critical assets. Here are some the operation and management benefits of facility management software to an organization.

Benefits of facility management software to management

-

Extend the assets’ life Span

Facility management software gives you tools to effectively plan and implement OEM (Original Equipment Manufacturer) recommended preventive maintenance schedules. This helps to slow down asset deterioration, maintain optimal asset working & safety condition and ultimately extend the lifespan of the asset.

-

Reduce the frequency of asset breakdown:

With a facility management software, you can progressively migrate your maintenance activities from reactive to proactive, crisis mode to planning mode and disruptive to predictive. Thereby minimizing asset breakdown and the associated repair cost, embarrassment and overall equipment downtime impact on the business.

-

Reduce maintenance cost:

Reduce your facilities maintenance cost by 5 – 15% in the first year and up to 30% by the third year. Save cost on reactive and downtime maintenance, reduce personnel overhead, reduce the cost of paper printing, handling, storing and retrieving.

-

Save personnel time spent on administrative functions:

Studies have shown that half of maintenance personnel time is spent on administrative activities such as documentation, scheduling, planning, communication, resource assignment and coordination. facilities management software provides tools to automate all these administrative activities, thereby freeing up your personnel time for use in activities that directly benefit the bottom line.

-

Cut down on inventory fraud and leakages:

Easily monitor and control inventory activities from anywhere at any time. Report stock usage, receive automated low stock notification to avoid running out of stock of critical spare parts. Configure maximum stock level for inventory items to avoid overstocking and thus improve cash flow.

-

Gain control and better Insight through management reports:

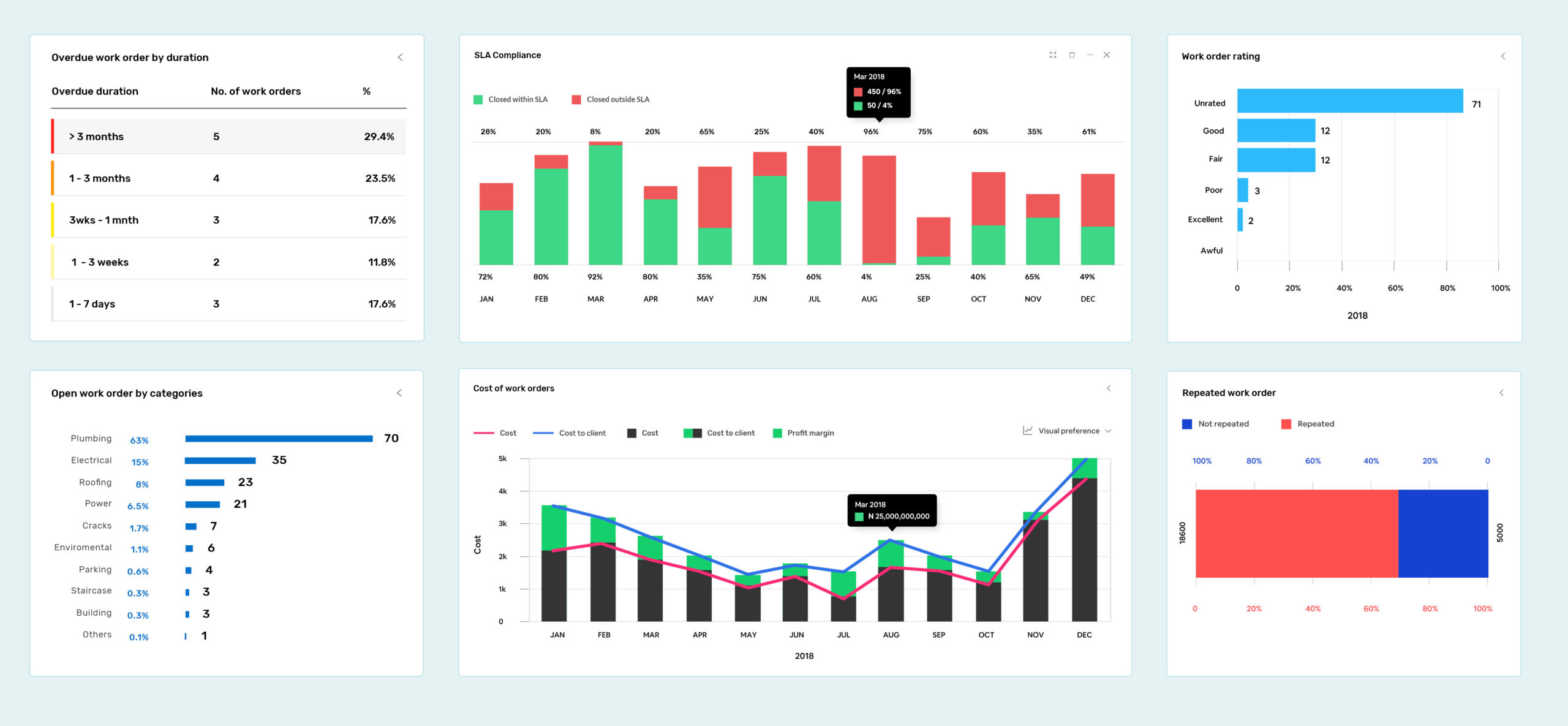

Quickly generate facility & asset performance report, objectively appraise the performance of your technicians & external contractors, monitor SLA compliance and escalate non-compliance.

Operational benefits of facility management software

- Improve the tracking of assets’ location, tag number, serial, manufacturer, supplier etc.

- Submit maintenance or items requests through a simple online interface.

- Easily create, assign, cost, and monitor maintenance jobs.

- Report assets’ maintenance history, spare parts used and cost.

- Schedule OEM preventive maintenance schedules & inspections, and then receive automated reminders close to the due date.

- Receive and track equipment operator’s feedback and job satisfaction ratings.

- Create central database for vendors & technicians and objectively appraise their performance using criteria such as SLA compliance, client satisfaction rating and frequency of repeated jobs.

- Monitor stock purchase, track stock usage and receive automated advice on minimum stock reorder level and maximum stock level for spare parts, accessories and other consumables.

- Easily collaborate with all stakeholders via SMS and Email.

If you are interested in implementing a Fleet Management Software in Nigeria kindly visit https://sysservesolutions.com/instanta/cmms or email:sales@sysservesolutions.com to learn more and request a demo.